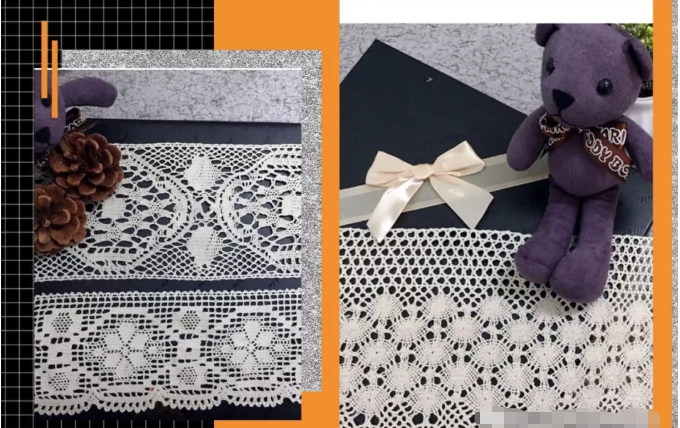

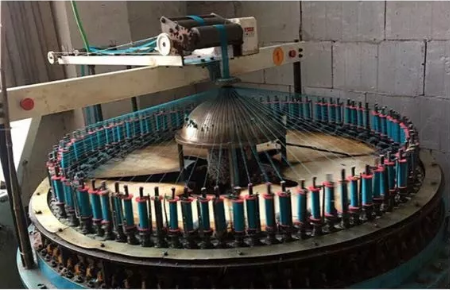

Cotton lace, also known as hook shuttle lace, originated in Japan beach shoes, produced by the disc machine.This kind of lace is made of high-quality combed cotton thread, with good color fastness, fine workmanship, soft hand feeling, novel pattern, various styles, and widely used in fashion, underwear, home wear, children’s wear, bedding, socks, umbrellas, toys and other handicrafts.At present, the main production models are divided into two types: plate machine and computer machine, and according to the process type, there are three types: 64 ingot, 96 ingot and 128 ingot.

The working principle of the disc machine is spindle weaving, which is similar to the process of knitting sweaters for girls.Its basic unit is the intersection of two lines and the transaction point, each type of lace is the intersection point arrangement and combination, in the machine (disk machine), it is the performance of the spindle rotation.The rotor rotates adjacent spindles so that they exchange positions and form an intersection point. Different rotation combinations result in different patterns.

The main material is usually cotton thread, but it can also be human cotton thread, polyester thread, gold and silver thread or mixed ingredients, etc. Different materials can be woven into various exquisite lace patterns.In addition, the raw materials have different thickness, we usually called “count”.For example, the number of cotton yarn commonly used from 21, 32, 40, 60 to 100.The higher the yarn cost and the lower the output, the higher the unit price (also depending on the pattern and width).

The dyeing of cotton lace is divided into pre-dyeing (also known as yarn dyeing) and post-dyeing (commonly known as soil dyeing).

Dyed yarn dye is before (colored yarn dyed quantity for plain about 3000 y, depending on the pattern width and count to float), via solid color oil, drying, after confirm the color yarn, and lines, then the spindle, then change equipment, and computer debugging production and so on a series of programs, the whole process generally takes 3-5 days to have normal production.Compared with post-dyeing, the advantages of colored yarn lie in the uniform color of lace, good color fastness, handle, specifications, and more stable quality.

And then dyeing (soil dyeing) that is lace woven billet dyeing, this practice is often because of a small number of orders, large loss of color yarn or customers urgent delivery.After dyeing needs to pay attention to the lace when the billet must be pre-relaxed and the length of the shrinkage, generally 5-8%.After the color is confirmed, manual finishing, ironing, measurement and packaging are carried out.It has the advantage of being unlimited in number.But the shortcoming is very many, for example easy to cause the color difference, the color flower, the width is uneven and the ironing is difficult and so on.Therefore, sometimes the cost of soil dyeing is higher than color yarn.

Post time: Aug-14-2020